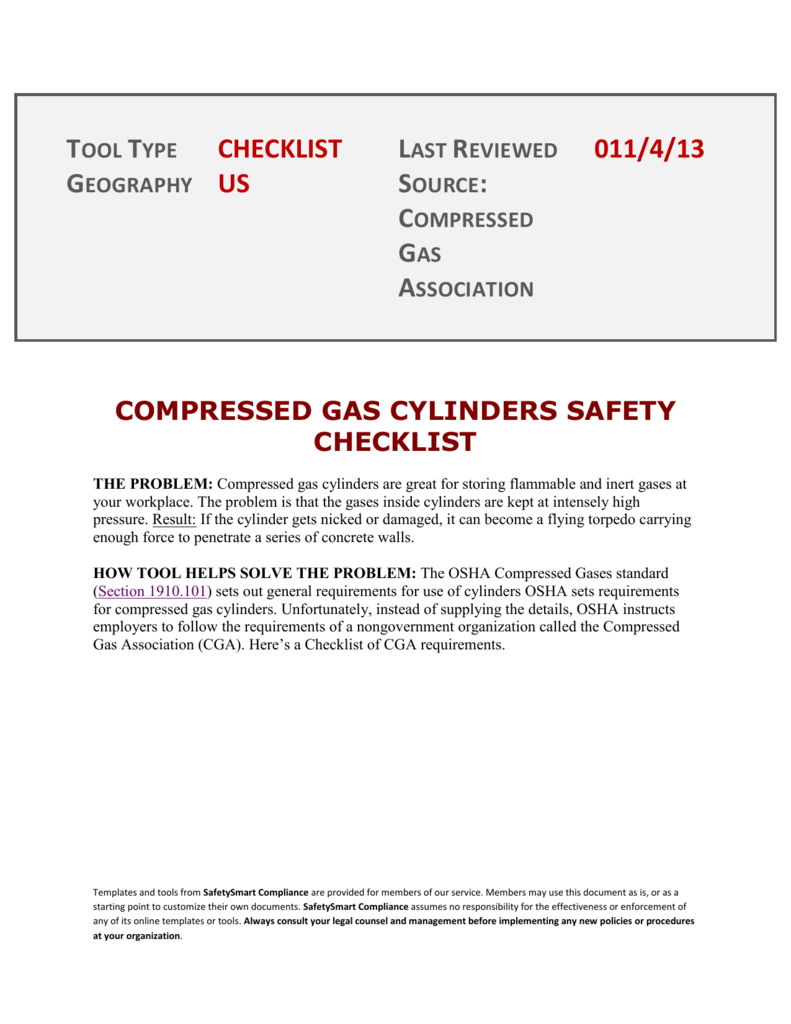

The occupational safety and health administration osha references general requirements for compressed gases in 29 code of federal regulations cfr 1910 101 and specific gas requirements are found in.

Compressed gas cylinder storage requirements osha.

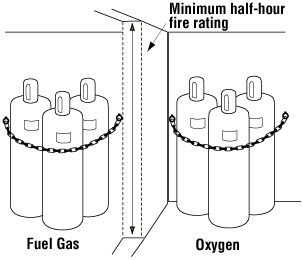

Include firewalls for cylinders with contents that pose different types of hazards.

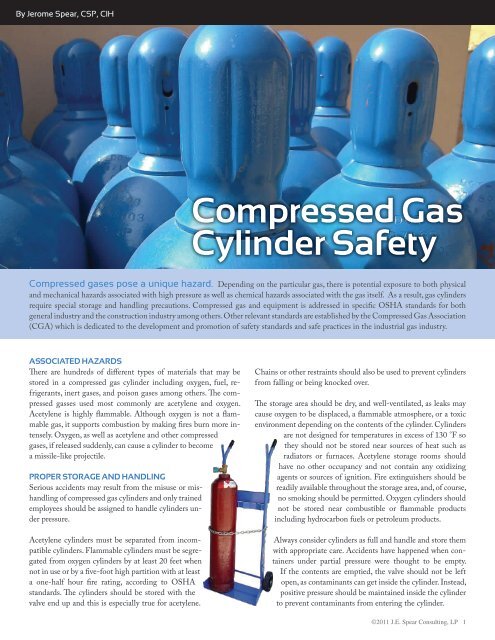

Osha compressed gas cylinders common oversights of safety issues found within osha regulations excerpts the actual osha standard 1910 253 b 2 ii says inside of buildings cylinders shall be stored in a well protected well ventilated dry location at least 20 6 1m feet from highly combustible materials such as oil or excelsior.

Industrial gas cylinders are color coded to provide identification at a glance.

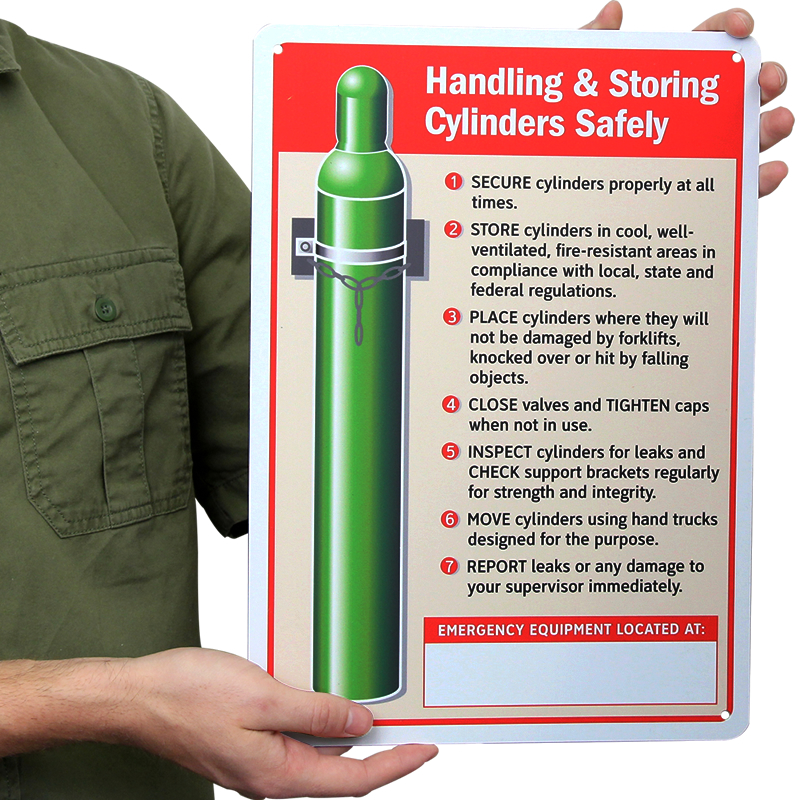

Regulators cylinders and cylinder valves must be inspected regularly to ensure safe operation.

29 cfr 1910 102 acetylene.

29 cfr 1910 103 hydrogen.

29 cfr 1910 105 nitrous oxide.

Here are the compressed gas cylinder storage tips.

29 cfr 1910 104 oxygen.

Keep the tanks away from the sun flames sparks and areas that reach and exceed 125 degrees fahrenheit.

Oxidizers should not rest within twenty feet of gases which are flammable.

The in plant handling storage and utilization of all compressed gases in cylinders portable tanks rail tankcars or motor vehicle cargo tanks shall be in accordance with compressed gas association pamphlet p 1 1965 which is incorporated by reference as specified in sec.

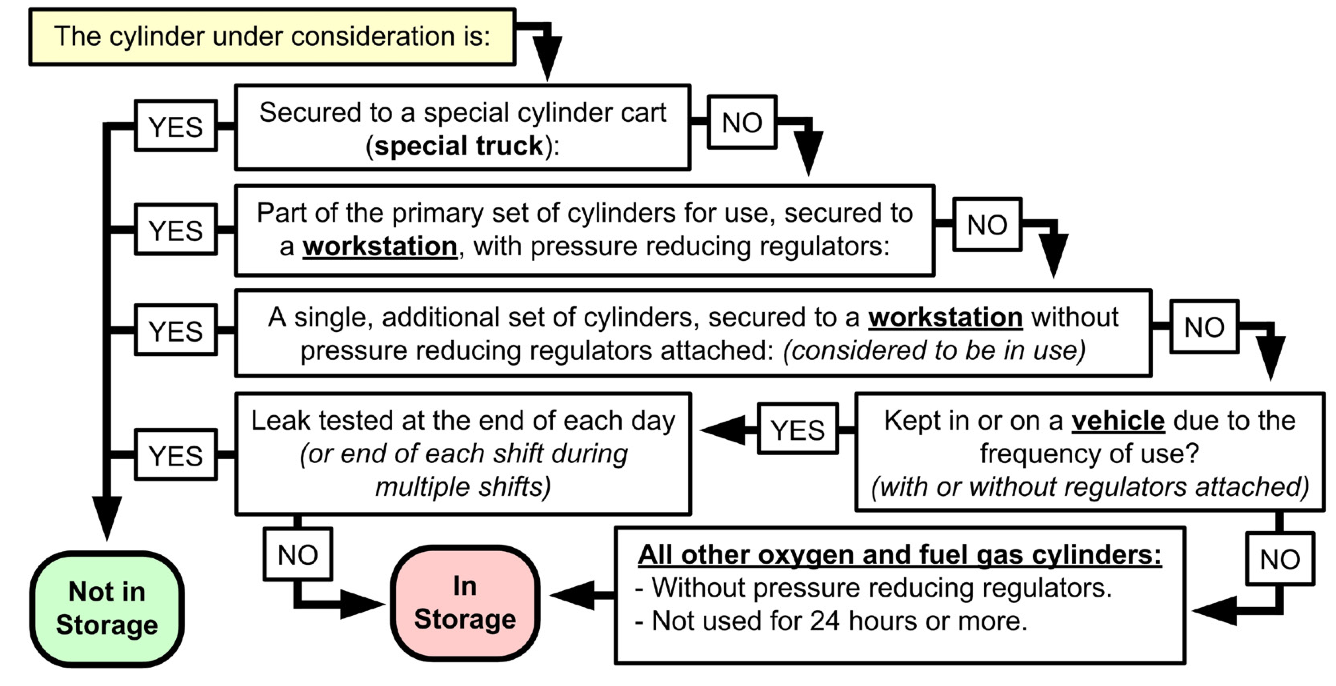

Osha standard 1910 101 compressed gases and cylinders must be properly stored transported and used to prevent injury and accidents.